In an industry where time is a critical factor, the construction sector is constantly striving to find innovative methods to deliver projects more rapidly, all without compromising on quality. One solution that has been gaining significant traction in recent years is the use of prefabricated wall panels. Let’s dive deeper into how these time-saving components are shaping the future of construction.

The Prefab Advantage

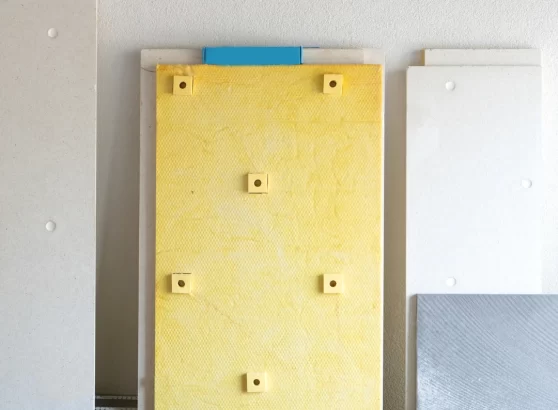

The concept of prefabrication is not entirely new, yet its full potential is only being realized now. Prefabricated wall panels are manufactured off-site in a controlled environment, then shipped to the construction site ready for installation. This method streamlines the building process, significantly reducing the time spent on site and accelerating the overall construction schedule.

By utilizing prefabricated panels, large construction projects can be completed in record time. This is a significant advantage, especially when working on major commercial buildings or institutional projects where delays can result in substantial financial losses.

Minimizing Weather Delays

One of the biggest challenges in any construction project is the weather. Rain, snow, high winds – all these can cause significant delays. However, with prefabricated wall panels, a significant portion of the work is done indoors, in a factory setting. This approach makes the construction process less susceptible to weather-related delays, allowing construction to continue rain or shine, and ensuring that timelines remain on track.

Improved Planning and Scheduling

Prefabrication is a game-changer when it comes to project planning and scheduling. With traditional construction methods, there are a lot of moving parts to coordinate, from materials delivery to labor schedules.

However, with prefabricated wall panels, components arrive on-site exactly when they’re needed and not before. This just-in-time delivery minimizes delays associated with storage or materials arriving too early or too late. The result is a smoother, more predictable construction schedule, which makes it easier for project managers to plan and monitor progress.

Reduced Labor Time

Labor costs are a significant portion of any construction project budget. The use of prefabricated wall panels drastically reduces on-site labor time. This not only saves time but also reduces labor costs, creating a win-win situation for project owners and contractors alike.

Moreover, labor can be more effectively managed in a factory setting, with workers able to focus on specific tasks without the distractions or challenges of a traditional construction site. This can result in higher productivity levels, further contributing to time savings.

The Impact on the Construction Industry

The time-saving benefits of prefabricated wall panels are having a profound impact on the construction industry. Contractors are able to deliver projects faster, which not only enhances their competitive advantage but also leads to higher client satisfaction levels. Meanwhile, project owners benefit from faster project completion times, which can translate into earlier occupancy and therefore quicker returns on investment.

In Summary

In the race against time, prefabricated wall panels are proving to be an invaluable tool. By streamlining the construction process, minimizing weather delays, improving planning and scheduling, and reducing labor time, these panels are revolutionizing the way we build.

The construction industry has always been about innovation, and prefabricated wall panels represent the next step in this ongoing evolution. They’re transforming the way we think about construction, allowing us to build faster, more efficiently, and with fewer resources. In an industry where time is money, that’s a proposition that’s hard to ignore.

Contact RGZ Cambridge today for all your prefabricated wall panel needs: We are industry leaders in Commercial and Residential projects. Call us today: 613-695-5544 or reach us via this page.