Top-Quality Prefabricated Wall Panels for Ottawa Builders: Why RGZ Cambridge Stands Out

As the construction industry continues to evolve, builders are always seeking ways to improve efficiency, reduce costs, and enhance the quality of their projects. One of the most effective ways to achieve these goals is by using prefabricated wall panels. RGZ Cambridge offers top-quality prefab wall panels in Ottawa that meet the needs of both residential and commercial builders. In this blog, we’ll explore why RGZ Cambridge’s prefabricated wall panels are a game-changer for construction projects and how they set themselves apart from the competition.

What Are Prefabricated Wall Panels?

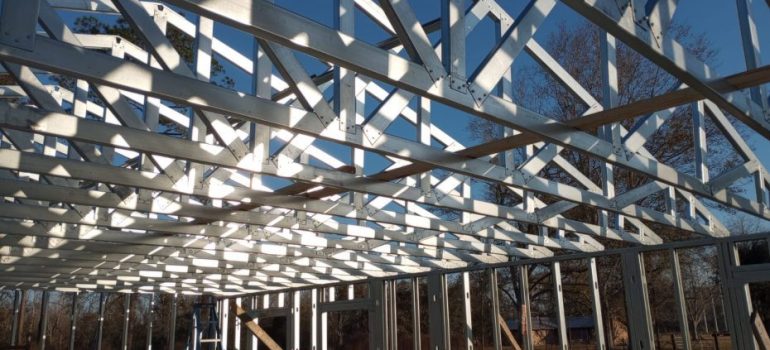

Prefabricated wall panels, often referred to as prefab walls, are pre-assembled sections of a building’s wall that are manufactured in a controlled environment. These panels are designed, engineered, and tested for strength and durability before being transported to the construction site for quick and easy installation. Whether it’s for residential homes or large commercial buildings, prefab wall panels provide significant time and cost savings while ensuring high-quality results.

At RGZ Cambridge, we specialize in delivering premium prefab wall panels in Ottawa and Cambridge, offering superior construction solutions for builders who want to streamline their processes while ensuring lasting results.

Why RGZ Cambridge’s Prefabricated Wall Panels Stand Out

-

Superior Quality and Durability

When it comes to construction, durability is essential. RGZ Cambridge’s prefab wall panels are manufactured with high-quality materials that ensure lasting strength and stability. Our panels undergo rigorous testing during the manufacturing process to ensure they meet or exceed industry standards. Builders can rest assured that their projects will benefit from the strength, resilience, and durability of RGZ Cambridge prefab walls.

Our prefab walls in Ottawa are designed to withstand the harshest conditions and offer excellent performance over time. Whether it’s extreme weather, moisture, or regular wear and tear, RGZ Cambridge’s panels are built to last. This makes them an ideal choice for projects requiring long-term durability.

-

Customization Options for Every Project

Every construction project is unique, and RGZ Cambridge understands the importance of customization. We offer tailored prefab wall panels that can be adjusted to meet the specific needs of your residential or commercial project. Whether you’re working on a modern residential building, a commercial space, or an industrial structure, our panels can be customized to fit the architectural style, design, and structural requirements of your project.

Our flexibility in customization allows builders to achieve the desired aesthetics and functionality while maintaining the structural integrity of the building. From insulation properties to panel sizes and finishes, RGZ Cambridge gives you the ability to create a truly unique and functional space.

-

Speed and Efficiency of Installation

One of the main reasons builders choose prefab wall panels is the efficiency they bring to a construction project. Traditional building methods often involve extensive on-site labor and prolonged installation times. With RGZ Cambridge’s prefab walls in Ottawa, builders can significantly reduce the time it takes to complete a project.

Our prefab wall panels are manufactured off-site, which reduces the complexity and duration of on-site construction. The panels are delivered ready for installation, which means less time spent on-site, fewer labor hours, and fewer delays. This speed of installation allows builders to complete projects on schedule, resulting in cost savings and a more streamlined building process.

-

Sustainability and Environmental Responsibility

Sustainability is becoming increasingly important in construction, and RGZ Cambridge is committed to providing eco-friendly solutions. Our prefab wall panels are manufactured in a controlled environment, which reduces waste and minimizes material wastage compared to traditional construction methods. Additionally, the materials used in our panels are designed for energy efficiency, helping to reduce the overall carbon footprint of the building.

Using prefab walls in Ottawa also leads to a more efficient construction process, resulting in less disruption to the surrounding environment. The panels are pre-engineered and require less time on-site, reducing energy consumption and minimizing the environmental impact of the project.

How RGZ Cambridge Enhances Ottawa Construction Projects

RGZ Cambridge’s prefabricated wall panels provide a comprehensive solution for Ottawa builders who want to improve their construction processes. We offer expertise in custom design, high-quality manufacturing, and efficient installation, all backed by our commitment to sustainability and client satisfaction.

Whether you’re a residential builder looking to complete a project on time and under budget or a commercial contractor seeking a reliable, high-quality solution, RGZ Cambridge provides the ideal choice for prefab walls in Ottawa and Cambridge.

FAQs about RGZ Cambridge’s Prefabricated Wall Panels

Q: Can RGZ Cambridge’s prefab wall panels be used for both residential and commercial projects?

A: Yes, RGZ Cambridge’s prefab wall panels are versatile and can be used for a wide range of projects, including both residential homes and commercial buildings. Our panels can be customized to meet the unique needs of your project, whether it’s a home, office, or retail space.

Q: How do prefab wall panels contribute to construction cost savings?

A: Prefabricated wall panels reduce labor costs and installation time, which in turn lowers overall construction costs. Since the panels are manufactured off-site, builders can also save on material waste and site preparation. The speed of installation allows for faster project completion, which helps to reduce overall costs.

Q: Are RGZ Cambridge’s prefab wall panels energy-efficient?

A: Yes, RGZ Cambridge’s prefab wall panels are designed with energy efficiency in mind. The materials used in the panels offer excellent insulation properties, which helps to reduce energy consumption and lower heating and cooling costs for the building.

Client Testimonials

- Paul H., Commercial Contractor

“We’ve used RGZ Cambridge’s prefab wall panels on multiple commercial projects, and they’ve been a game-changer. The quality and durability of the panels are unmatched, and the speed of installation has saved us a lot of time and money. I highly recommend RGZ Cambridge for any construction project.” - Emily R., Residential Builder

“RGZ Cambridge provided us with the perfect solution for our latest residential development. The prefab walls were customized to fit our design perfectly, and the installation process was quick and efficient. Our project was completed on schedule, and the clients were thrilled with the final result.” - Michael T., Architect

“As an architect, I rely on high-quality, customizable materials for my projects, and RGZ Cambridge delivers every time. Their prefab wall panels are durable, energy-efficient, and can be tailored to meet the specific needs of the design. Working with them has been a fantastic experience.”

Get Your Free Quote Today

If you’re ready to take your construction project to the next level with high-quality, customizable prefab wall panels, RGZ Cambridge is here to help. Our team is available to discuss your project needs and provide you with a free quote.

Contact us today for a free quote!

📞 Phone: (613) 695-5544

📧 Email: info@rgz-cambridge.com

Let’s work together to make your next large-scale construction project a success.

For more info, visit our Facebook page.

Discover why RGZ Cambridge is the trusted name in commercial and residential construction in Ottawa.